Beyond the Baseline: Designing Your Ultimate Home Pickleball Sanctuary with Keystone Sport Construction

Read More

Pickleball’s meteoric rise has turned it from a niche backyard game into a nationwide sensation. As court owners, facility managers, and avid players, you know that the investment in a quality court is significant. But what happens when the temperatures drop and the snow begins to fall?

For many, winter means the end of outdoor play. However, winter is actually the ideal time to plan and execute essential court maintenance, specifically resurfacing. A professional resurfacing job, completed before the harshest winter weather sets in or scheduled for the early spring thaw, is the single most important step you can take to protect your asset and prepare for peak season performance.

This guide from Keystone Sports Construction explores the critical process of resurfacing pickleball courts to maximize their lifespan, enhance player safety, and get them ready to dominate the next playing season.

The surface of a pickleball court is constantly battling the elements, and winter is arguably its toughest adversary. Here’s why proactive resurfacing is non-negotiable for long-term court health:

This is the number one enemy of any outdoor court. Water seeps into tiny cracks, pores, and compromised areas of the acrylic surface. When the temperature drops below freezing, this trapped water expands, exerting immense pressure. When it thaws, it contracts, leaving the cracks larger. This cycle repeats, turning minor imperfections into major, structural surface damage, such as:

While the sun is less intense in winter, year-round ultraviolet (UV) radiation breaks down the chemical bonds in the acrylic color coating. This leads to fading, chalking, and a general degradation of the surface integrity. Resurfacing applies a fresh layer of UV-resistant acrylic to protect the asphalt or concrete base beneath.

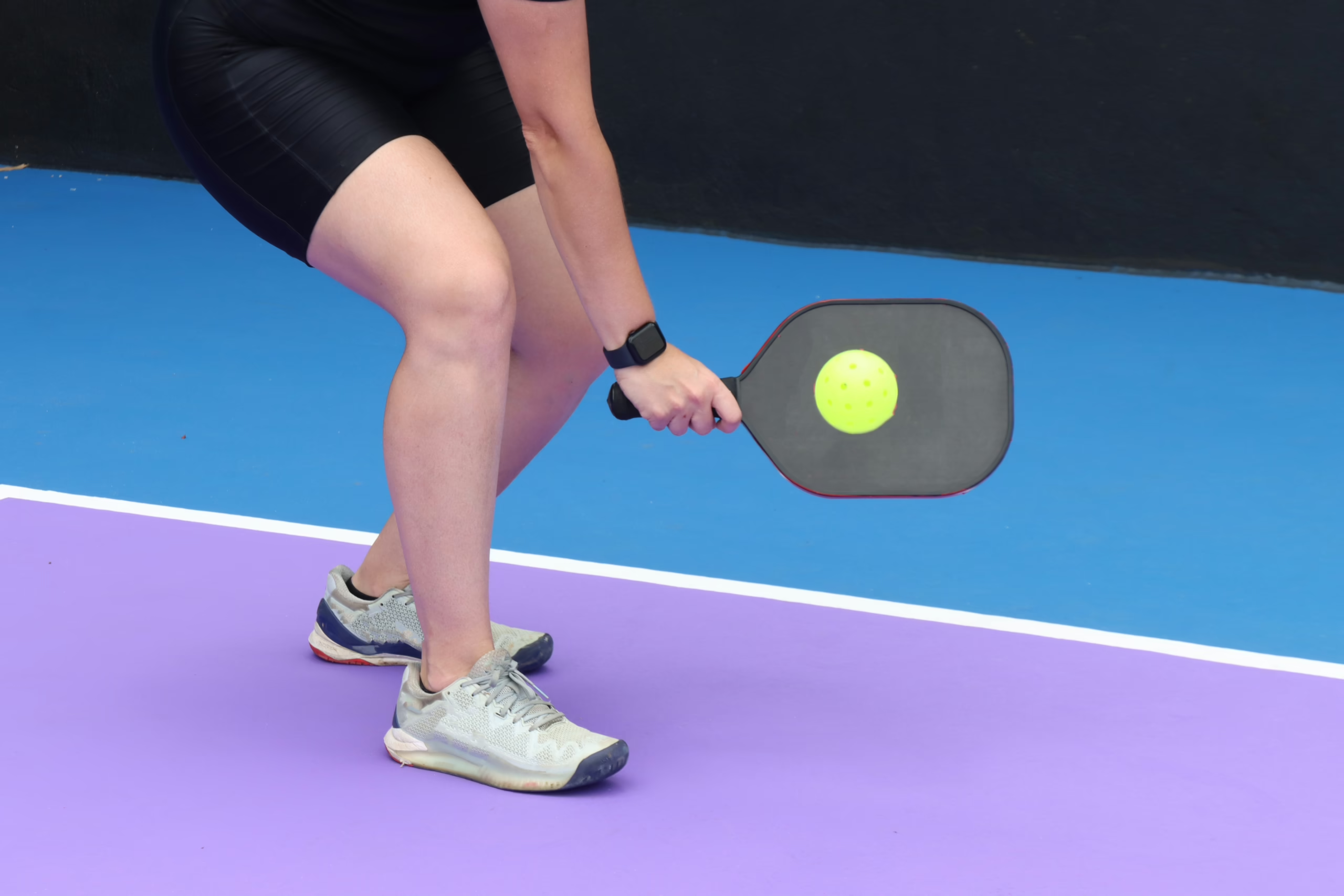

A cracked, worn, or slick surface is a liability. Pickleball court resurfacing near Virginia restores the optimal texture (called the “sand profile”) required for proper foot traction, which prevents slips and falls. It also corrects minor undulations that can cause unpredictable ball bounces, restoring the fast, true play that high-level pickleball demands.

At Keystone Sports Construction, we follow a meticulous, multi-step process to transform your worn court into a high-performance playing field built to last. Our approach is designed for maximum adhesion, durability, and a beautiful finish.

Before any new material is applied, the existing court must be thoroughly cleaned. This involves removing all loose debris, mildew, algae, and any other contaminants. We often use a power wash followed by specialized cleaning solutions to create a perfectly clean and porous surface, ready for the new coatings to bond securely. Preparation is the key to longevity.

This is the most critical step. We utilize industry-leading crack repair systems designed for sports surfaces. Depending on the type and severity of the cracks, we may use:

The resurfacer is the foundational coat. This highly filled, pigmented acrylic compound is applied to smooth out the base, fill the finer pores of the asphalt or concrete, and provide a uniform texture. This layer acts as the bridge, establishing a strong, cohesive bond between the old surface and the new color coats.

We then apply two or more coats of 100% acrylic color surface system. These layers contain specialized aggregate (sand) that determines the court’s texture, pace, and grip. We precisely tailor the sand profile to meet official standards and player preference, delivering:

The final touch is the official court lines. Using specialized line paint that contrasts sharply with the surface color, our technicians meticulously measure and mark the 44-foot by 20-foot pickleball court dimensions. Precision in line marking is essential for tournament-level play.

While resurfacing requires specific temperature windows, the winter months offer an invaluable opportunity for planning and securing your slot.

A pickleball court resurfacing is not merely a cosmetic fix; it is a vital, preventative investment. By addressing surface deterioration caused by the freeze-thaw cycle, UV exposure, and heavy play, you are extending the court’s life by several years, postponing the far more expensive cost of complete court reconstruction.

Keystone Sports Construction delivers proven expertise and high-quality materials, utilizing techniques perfected over decades of building and maintaining world-class sports surfaces. Do not let the harsh winter ruin your investment in your pickleball court surface.

Take the first step toward a stunning, high-performance court surface for the upcoming season. Contact Keystone Sports Construction today to schedule your complimentary off-season court assessment and secure your spot on our spring resurfacing schedule.